Dovilė Eitmantytė UAB Kitron, Lithuania

One of the Bridges 5.0 Teaching Factory interventions has already started in Kitron UAB, a Lithuanian electronics and manufacturing services company. Kitron’s innovative training programme for new employees was successfully launched in December 2024.

The intervention is being performed in cooperation with HybridLab and the Lithuanian Confederation of Industrialists.

The main tasks of the intervention are to provide new employees with skills to empower them through decision making and working with digital technologies in response to Industry 5.0.

Within this framework, the focus is on these aspects: human centric job roles, environmental sustainability and production resilience, as well as social factors. The programme outline can be found in the following table:

| No. | Training topic: | Skills to be implemented | Related Industry I5.0 directions / pillars |

|---|---|---|---|

| 1 | Introduction to Kitron (e.g. company values, history, structure, leadership encouragement events and initiatives) | Behavioural / Social skills | Continuous improvement / company social responsibility |

| 2 | EDS Safety/Requirements | Technical knowledge | Resilience |

| 3 | Environmental protection, LEAN (5S), occupational safety | Behavioural / Social skills | Recycling audit results / Energy cost per employee |

| 4 | Electromechanical basics (e.g. Terms and classification of components) | Technical knowledge | Resilience |

| 5 | Manufacturing Execution System usage skills (Factory Logix, FLX) | Digital skills | Resilience |

| 6 | IT usage skills (e.g. Intranet, cyber security, email, IT help desk etc.) | Digital skills | Resilience |

| 7 | Quality management system (e.g. ISO standards) | Technical knowledge | Human / Social |

| 8 | Documentation reading | Technical knowledge | Human / Social |

| 9 | ERP (IFS) system usage skills | Digital skills | Resilience |

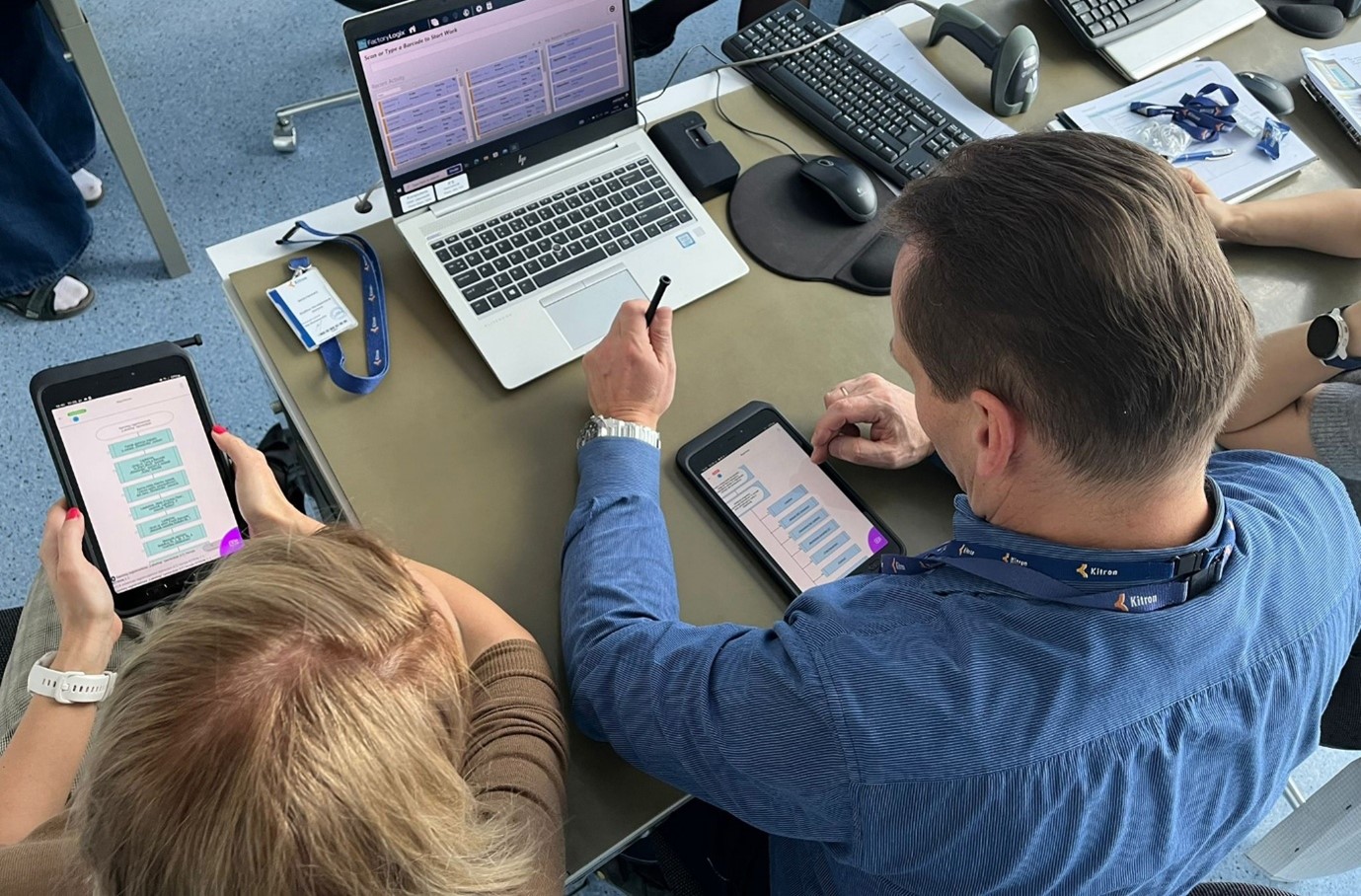

HybridLab (a Bridges 5.0 partner) created and validated the training programme based on a peer-to-peer learning methodology. Together with the Kitron team HybridLab delivered the programme in Kitron UAB. All new employees are split into groups of three and have different roles: the instructor, the learner, and the observer. The roles are rotating so that each member can learn the subject from different angles and perspective.

Simulated workplaces are created in the training classes to help participants learn new skills in practical, work related situations. Mobile applications and computer programs are used both for learning theoretical topics and for performing practical tasks (algorithms) in groups.

Related articles

February 28, 2026

February 25, 2026

February 25, 2026