BRIDGES 5.0 is dedicated to evaluating and enhancing two established forms of training intervention, namely Teaching and Learning Factories. These interventions are designed to address the skills required in manufacturing industry, targeting both individual companies and associations of public-private organisations. The objective of these interventions is to facilitate skill adaptation in response to the Industry 5.0 paradigm shift. To achieve this, a comprehensive framework is being developed to translate Industry 5.0 concepts and strategies into practical activities.

Within this framework, the focus is on job transitions, the digitisation of work, and three critical aspects: human-centric job roles, environmental sustainability, and production resilience. Social factors are also considered. Additionally, the specific needs of companies and associations are taken into account in terms of content delivery and skills development. This considers both institutional and personal/social dimensions.

BRIDGES 5.0 targets four primary groups for these interventions: managers and engineers, workers, students, and job seekers. The transition to Industry 5.0 necessitates the enhancement of existing training programs, which is the core mission of Bridges 5.0.

Intervention focus

BRIDGES 5.0 primarily concentrates on training related to production environments. The interventions have been created in the context of Industry 4.0 and have a focus on improving technology use. However, we argue that the success of Industry 4.0 technologies depends on the ability of users to understand the organisational context in which they are situated, and that their deployment and use is ‘adaptable’ rather than given. Empowering employees to express their views and to harness their tacit knowledge in shaping how the technology is deployed means that they must learn to participate [1, 2]. This, as well as enhancing the alignment of technologies with the goals of the company, is therefore central to BRIDGES 5.0’s approach, focusing on operations, but potentially encompassing the entire value chain:

Design

Supply

Production (Operations)

Dispatch

Use phase support

End of life

BRIDGES 5.0’s Teaching and Learning Factory interventions will therefore be updated with this new perspective. Trainees will gain insights into how – and why – they should act to ensure that technologies contribute to the core pillars of Industry 5.0: human centricity in the workplace, environmental sustainability and resilience, and that as users they need to participate in value sharing.

The framework aims to transform the concepts of Teaching and Learning Factories into a procedure that promotes experiential learning, specifically tailored to identify skills for Industry 5.0. These two training procedures are rooted in problem-solving and replicating manufacturing environments. They will be integrated with existing training systems, assessing their readiness to incorporate Industry 5.0 as a strategic approach, often in parallel with maintaining Industry 4.0 as an implementation and communication principle.

- Teaching Factory: A dynamic exchange where industry practitioners teach students, and students and faculty teach practitioners. This collaboration occurs online over an extended period, featuring regular sessions and continuous interaction between industry and academia [1].

- Learning Factory: A concept where university facilities replicate manufacturing environments, enabling collaboration between academia and industry in specific courses aimed at imparting manufacturing concepts, trends, and knowledge in an academic setting [2]. It resembles a hands-on workshop.

Implementation plan

The interventions for company and association training consist of five distinct phases: requirement gathering; identifying the implications of Industry 5.0 for current systems; designing the procedure; conducting pilot training sessions; and evaluating the outcomes. The results of these interventions will serve as the basis for extracting best practices for integrating Industry 5.0 and shaping the future of European industrial strategies. This knowledge will be disseminated through three main publications, including a policy brief on the benefits of Teaching and Learning Factories 5.0, and a Handbook of Future-Proof Interventions.

Generalisation

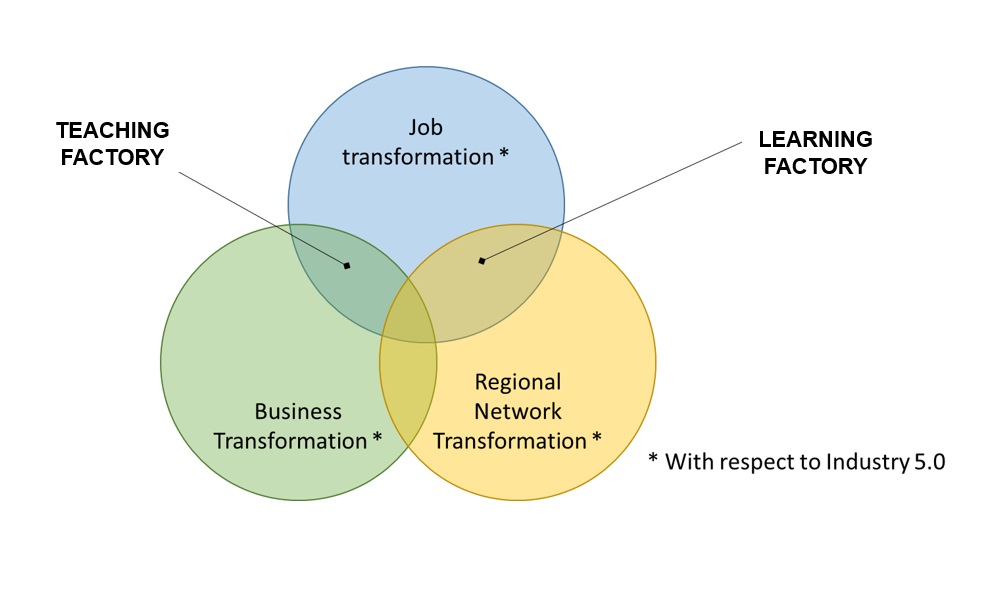

The methodology adopted acknowledges that job transformation is intertwined with the larger ecosystem. Therefore, during the intervention, besides addressing job transition aspects [3], consideration will be given to the feasibility of the intervention within the broader context. This is summarised in the following diagram:

Related articles

May 11, 2024